6 Considerations Before Installing Concrete Lego Blocks

We’ve spoken in previous blogs about the versatility and cost effectiveness of using Concrete Lego Blocksfor different projects, and in this blog we’ll discuss some of the aspects that must be considered before the blocks are fitted.

Size matters

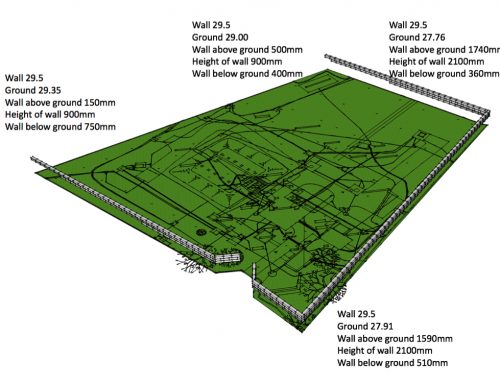

The first consideration when thinking about our solution is what you’ll be using it for and what size area it needs to cover. We can work in M2 or per block, so provided you have the dimensions of your walls we can work out the rest for you and ensure there is enough coverage for your project.

Access All Areas

One piece of feedback our drivers always provide is whether the access into the site was suitable or not. Our trucks are over 3m wide and 15m long. If we are using a Hiab truck, there needs to be sufficient room for the mounted crane to be able to pick up and drop the blocks into place. If access is restricted, then it can be difficult to get all the blocks fitted or unloaded correctly.

On The Level

The blocks themselves don’t have to be bonded like traditional blocks and bricks, however one thing they have to be laid on is, flat ground. It’s essential that the ground to be laid on, is clear and flat. In the majority of projects, we work on, the site is already flat and this isn’t given a second thought, however if you know that your land is uneven or bumpy, intermediate work will need to be carried out to level and flatten the ground before fitting.

Wind of Change

Most blocks will be laid and left in place for a long time, however there are occasions when your business needs change, and you need to think about moving the blocks to a new home. We have found this especially true of Waste Management companies whose service offering may change from time to time as they increase the amount of materials coming into their sites.

Just Bring it!

One of the most important questions we ask at the beginning of the entire process is whether the blocks are being delivered and fitted or just delivered. If the blocks are to be delivered then there are a number of factors you need to take into account, such as how you will unload the blocks and build them. If you would like delivery and fitting, will our team have good access to the site and someone on hand to give clear instructions on the final destination of the blocks? If you’re unloading yourself, we’ll lay the blocks on timbers or pallets so your forklift can unload them comfortably.

All the gear, no idea

If you do choose to fit the blocks yourself, don’t worry, it’s not rocket science, however there is a bit of a knack to it, so we’ll send you a fitting guide to give you clear instructions on how to fit the wall and what equipment you’ll need. If clients do wish to fit the blocks themselves they will generally need a forklift truck, and a block grab to attach to the forklift. We’re in the process of making this much easier for clients by casting bars into every block. A shackle chain can then be attached to the forklift which attaches to the bar in the block and can be moved easily enough.

In our experience of fitting Concrete Lego blocks, these tend to be the main considerations before installing our solution. Provided you have given the above some prior thought, delivery and installation of the Blocks tends to be a straightforward process.

If you would like to read more of our Frequently asked questions, visit our FAQ page here!

If there is anything you feel we may have omitted from the list above, when installing our solution, tell us about it on Twitter we’d love to hear from you.