Affordable Segregation Solutions – Go The Non Traditional Route

New Regulations

Since “the waste (England and Wales) amendment regulations in 2012 were released and became effective in 2015, Waste Management companies all over the UK are required to ensure correct segregation of their waste streams in depots all over England and Wales.

Each industry or service that produces waste is also entirely unique in what they can segregate and the guidelines for those storage measures.

This means that the ability to segregate cleanly and efficiently just became even more important to any company in England or Wales who house waste.

Everyone from Homeowners to large industrial organisations are being urged to ensure they recycle as much as possible, and cut down on waste. With countries in the EU alone wasting over 89m tonnes of food every year, and Britain near the top of this waste table, it’s easy to see why the issue over Waste Management and how to segregate this waste is such an important one right now.

Waste Management companies up and down the UK are expected to ensure correct segregation of waste materials too, which can be a costly expense.

Depending on the size and diversity of the Waste Management Company they may need to segregate a large number of different materials. Large companies such as Biffa and Veolia will deal with waste from Food, Hazardous waste, Material recycling to name but a few, so having the most effective segregation within their depots is absolutely paramount.

Challenges Faced

Even smaller Waste Management companies across the UK are finding it extremely challenging ensuring that their waste is segregated correctly and this only becomes more challenging as the business grows or they increase their service offering.

Lots of different structures and materials have been used over the years to ensure segregation is carried out efficiently and correctly however from the changes brought in earlier this year, it’s now imperative that Waste Management companies take a closer look at this area and just what is the best solution for their needs.

Solution

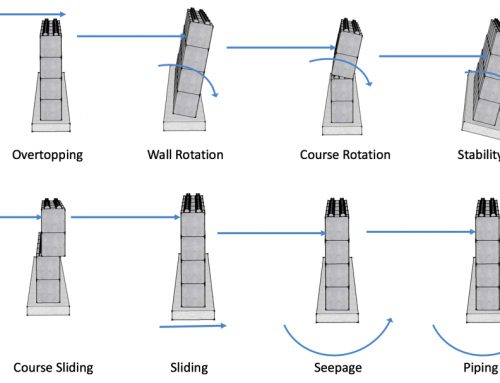

Historically Segregation would be made from bricks and mortar to breeze blocks or even temporary warehouses erected, However with increasing usage of heavy machinery being used within these companies to move around different types of waste, damage to the segregation bays and buildings is becoming more and more of a common occurrence and a costly expense which isn’t welcomed.

A solution is required that is strong, versatile, resilient and which had the ability to be moved around, as and when the business needs changed.

There are lots of companies all over the country who produce Pre-Cast concrete block solutions for this very purpose, however very few that can match the quality of the blocks we produce here at Blockwalls in terms of stability, strength and green credentials.

Here at BlockWalls we manufacture segregation solutions using Concrete Lego Blocks They come in different shapes and sizes which provide the Waste Management companies we work with different solutions to their Segregation needs. We also manufacture the blocks from 87% recycled material which also increases their green credentials in the process. In fact each block saves 100kg of Co2 the equivalent of a 500-mile car journey.

If you work in Waste Management and feel that our solution may be of interest, now or in the future, why not take a look at our product solutions here blockwalls.co.uk or call us on 0800 880 3135

If you would like to see how we have assisted some local and national waste management companies with their segregation needs click here to view our most recent case studies now.